FAF Products

FAF Clean Workbench ISO 5

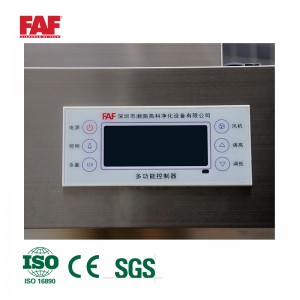

I. Product Introduction

A Clean Workbench, also known as a laminar flow bench or a dust-free workbench, is a specialized piece of equipment designed to provide a controlled, clean environment for sensitive tasks such as electronics assembly, laboratory work, or any process that requires contamination-free conditions. It uses a combination of HEPA filtration and laminar airflow to ensure that the work area remains free of dust and other particulates.

II. Product Advantages

1.Quasi-closed countertop can prevent external airflow from entering the clean area.

2.The wind speed is even and adjustable to maintain the cleanliness reaching class 100.

3. Product structure:HCM horizontal flow, VCW vertical flow.

III. Product Parameters

| Model | FAF-HCW-A1 | FAF-HCW-A2 | FAF-VCW-A1 | FAF-VCW-A2 |

| Outer(L*W*H)mm | 1035*740*1750 | 1340*740*1570 | 1040*690*1750 | 1420*690*1750 |

| Inner(L*W*H)mm | 945*600*600 | 1240*600*600 | 945*600*600 | 1340*640*600 |

| HEPA filter(mm) | 915*610*69 | 1220*610*69 | 915*610*69 | 1300*610*69 |

| Air flow(m³/H) | 1200 | 1600 | 1200 | 1600 |

| Velocity(m/s) /Noise(dB) | 0.45±20%m/s/52-56dB | |||

Note:This product is acceptable to non-standard customization

IV. Product Applications

Electronics Assembly: Used in the assembly of sensitive electronic components where dust can cause malfunctions.

Pharmaceutical Manufacturing: Essential in environments where contamination can compromise product quality or safety.

Biological Research: Provides a sterile environment for handling biological samples.

Semiconductor Fabrication: Critical in the production of semiconductors where particle contamination can affect chip performance.

Quality Control: Used in inspection areas where high levels of cleanliness are necessary.

V. FAQ

Q1:Why FAF?

A1:We have 20 years of production experience. Our factory is ISO9001 and ISO14001 certified. We have 20 technicians and engineers. We have a complete quality management system and after-sales service capabilities. We are your most suitable choice.

Q2:What is the difference between a clean workbench and a biological safety cabinet?

A2:The clean workbench is suitable for non-toxic and harmless operating objects. It is generally used in hospitals, biopharmaceuticals, food, medical science experiments, optics, electronics, sterile room experiments, sterile microorganism testing, plant tissue culture inoculation, etc. that require local cleanliness and Bacterial working environment of scientific research and production departments.

The use of biological safety cabinets is more inclined to laboratories, experiments with toxic and infectious viruses and bacteria, as well as experiments with volatile chemicals and volatile radionuclides.

Q3:What is the difference between the pressure setting of a clean workbench and a biological safety cabinet?

A3:The working area of most clean workbench is under positive pressure. The air at the top of the equipment is directly transferred to the work through the filtration system through the fan to form air pressure, and then breathed through the front window area.

The working area of the biological safety cabinet is under negative pressure, which prevents aerosols in experimental samples from escaping through the front window. The exhaust port passing through the work area and the exhaust port are filtered internally.