FAF Products

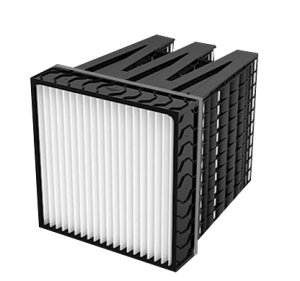

Gas Turbine Panel Air Filters

I. Product Introduction

Gas Turbine Panel Air Filters are high-performance filtration systems specifically engineered to protect gas turbines from harmful airborne contaminants. These robust filters serve as the first line of defense, ensuring clean air supply to turbine engines while maintaining optimal operational efficiency.Gas turbine panel filters are deeply loved by the market because of their larger air volume, smaller installation space, and good protection for terminal filters.

II. Product Advantages

1.Using new hydrophobic composite material, low resistance and long service life

2.Low wind resistance, wind resistance rises slowly under humid conditions

3.Hydrophobic and droplet separation provides waterproofing and drainage

4.Better protect the final filter and extend its service life

5.Pre-filters for most turbomachinery and gas turbine applications

III. Product Parameters

Common specifications, models & technical parameters

|

Model |

Size(mm) |

Air flow(m³/h) |

(Pa) Initial resistance |

Efficiency |

Media |

|

FAF-RC-18 |

287*592*96 |

1800 |

20~45Pa |

G4/F5/F6 |

Composite new materials |

|

FAF-RC-36 |

592*592*96 |

3600 |

Note: It can be customized according to user specifications and technical parameters.

IV. Product Applications

1. Power Generation

Combined Cycle Power Plants – Protects gas turbines from dust, sand, and salt corrosion.

Peaking Power Stations – Ensures optimal airflow for rapid turbine startup.

Off-Grid & Remote Power – Critical for turbines in desert or coastal environments.

2. Oil & Gas Industry

Offshore Platforms – Filters salt spray and hydrocarbon fumes.

Gas Compression Stations – Prevents fouling of turbine blades.

LNG Terminals – Maintains clean combustion air for efficiency.

3. Industrial & Marine

Cogeneration Plants – Reduces maintenance in CHP (Combined Heat & Power) systems.

Marine Propulsion Turbines – Handles high-humidity, salt-laden air.

Petrochemical Facilities – Filters corrosive chemical vapors (e.g., H₂S).

4. Aviation & Defense

Aeroderivative Gas Turbines – Used in military ships and mobile power units.

Aircraft Auxiliary Power Units (APUs) – Ensures clean air for turbine operation.

V.FAQ

Q1: How often should gas turbine air filters be replaced?

A: Typically every 6–12 months, but depends on:

Environment (desert = more frequent than urban).

Air quality monitoring (pressure drop ≥2x initial value = replace).

Q2: Can these filters handle extreme weather (sandstorms, hurricanes)?

A: Yes – Multi-stage filtration (pre-filter + HEPA/EPA) is available for:

Sand & Dust (MERV 8-16 pre-filters).

Salt & Moisture (hydrophobic coatings).

Q3: Do they improve turbine efficiency?

A: Absolutely – Clean air = better combustion, reducing:

Fuel consumption (up to 5% savings).

Turbine blade erosion.