Integrated fan filter units (FFUs) are the core terminal devices for air purification in modern electronic clean rooms, such as semiconductor, display panel, and integrated circuit production workshops. They are not just simple filters but functional units that integrate fans, high-efficiency/ultra-high-efficiency filters, casings, diffusers, and control devices.

I. What are Integrated Fan Filter Units?

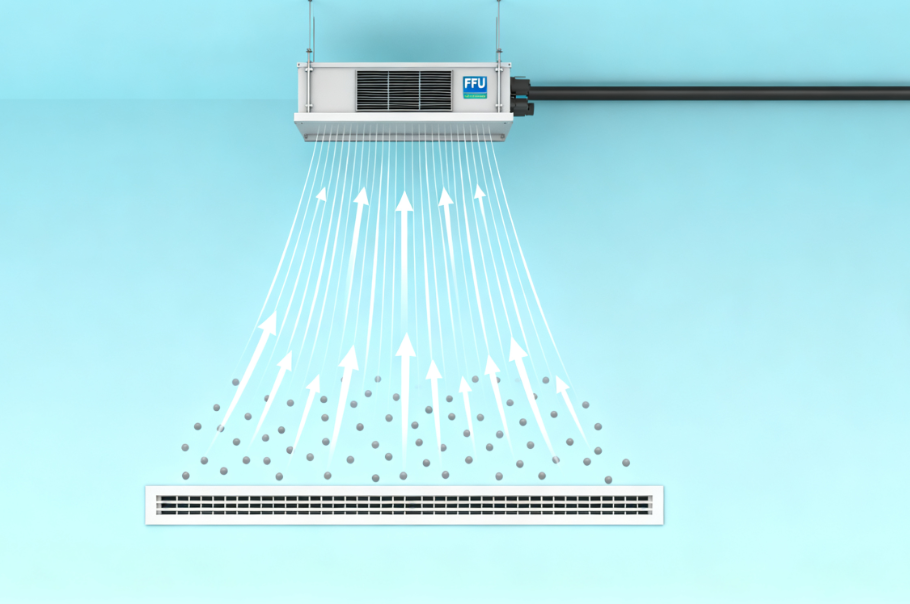

Traditional supply air outlets are “passive,” relying on the fan of the central air conditioning system to provide power to push filtered air into the room. In contrast, integrated fan filter units are “active,” with their own fans that actively draw air from the top static pressure chamber, pass it through the internal high-efficiency or ultra-high-efficiency filters (HEPA/ULPA), and then deliver it into the clean room in a uniform, vertical airflow.

Core Components:

1. Fan Section: Typically using brushless DC EC motors, which feature energy saving, stable speed regulation, long life, low heat generation, and low vibration.

2. Filter Section: The core is the HEPA (high-efficiency) or ULPA (ultra-high-efficiency) filter, which can filter particles larger than 0.3μm or 0.12μm with an efficiency of up to 99.99% to 99.9995%.

3. Casing and Structure: Usually made of cold-rolled steel with plastic coating or stainless steel, ensuring a robust structure, corrosion resistance, and dust-free production.

4. Diffuser: Located below the filter, it is often a perforated plate or a damping mesh, ensuring uniform airflow velocity (within ±10%) across the outlet surface.

5. Scatter Plate: It evenly diffuses the airflow downward to prevent vortex generation.

6. Control System: It can integrate speed controllers, PLCs, DDC controllers, etc., to achieve single or multi-unit control, monitoring operating status, air velocity, pressure difference, etc.

II. Technical Applications and Advantages of Integrated Fan Filter Units in Electronic Clean Rooms

The requirements for production environments in the electronics manufacturing industry are extremely stringent, as even the slightest dust can cause a sharp drop in product yield. The application of integrated fan filter units perfectly meets these demands.

1. Providing Stable and Uniform Vertical Unidirectional Flow (Laminar Flow)

- Application: In key process areas such as chip manufacturing, photolithography, and packaging, a ceiling full of FFU clusters forms a piston-like uniform airflow from top to bottom.

- Advantage: This airflow can quickly and effectively push down and remove particulate pollutants generated by equipment and personnel, preventing lateral diffusion and cross-contamination, and providing the highest level of local protection for products.

2. Achieving High Cleanliness Grades (such as ISO 1-5)

- Application:ULPA filters have a filtration efficiency of up to 99.9995% for particles larger than 0.1μm, which is the only feasible solution to achieve ultra-high cleanliness levels such as ISO 1 (Class 1) or Class 10.

- Advantage: It ensures that the concentration of airborne particles is kept below the limit, meeting the stringent requirements of nanoscale processes.

3. Flexibility and Modular Design

- Application: When the workshop layout is adjusted, equipment is updated, or the process is upgraded, it is very convenient to add, move, or replace the integrated fan filter units.

- Advantage: Compared with the traditional “fan + large HEPA supply air outlet + complex duct” system, the integrated fan filter unit eliminates the need for a large supply air static pressure chamber and most of the ducts, making construction faster and providing great flexibility for later modifications, reducing initial investment and modification costs.

4. Energy Conservation

- Application: Through EC motors, the air velocity and volume can be infinitely adjusted according to actual needs (such as during commissioning, low-load operation at night).

- Advantage:Reducing the air velocity during non-peak production times can significantly reduce fan energy consumption, resulting in much lower operating costs than traditional constant-volume systems. In addition, the elimination of most ducts also reduces system resistance and heat/cold loss along the way.

5. High Reliability and Easy Maintenance

- Application: FFUs usually operate in parallel modules, and the failure of one or several units will not cause the entire clean system to fail.

- Advantage: Maintenance can be carried out on individual integrated fan filter units without affecting the normal production of the workshop. It is safe to replace filters or repair units online. The intelligent control system can also monitor the operating status, air velocity, and filter terminal resistance of each integrated fan filter unit in real time, issue early warnings, and achieve predictive maintenance.

6. Reducing Building Height Requirements

- Application: Integrated fan filter units only require a relatively short technical interlayer (return air static pressure chamber) and do not need a large supply air static pressure chamber and complex duct space.

- Advantage: It can effectively reduce the height of the clean factory building, saving a significant amount of construction investment.

III. Application Considerations and Selection Points

When applying integrated fan filter units in electronic clean rooms, the following factors need to be considered comprehensively:

1. Cleanliness Grade Requirements: Determine whether to choose HEPA or ULPA filters and their efficiency based on the required cleanliness grade.

2. Air Velocity and Volume Control: Determine the face velocity (usually 0.35-0.55 m/s) according to process requirements and select fans with corresponding air pressure and volume.

3. Noise and Vibration:** Electronics workshops are sensitive to micro-vibration, so low-noise, low-vibration EC fan units should be selected, and effective vibration reduction measures should be taken.

4. Material and Structure:** Choose galvanized steel or stainless steel casings according to whether the environment is chemically corrosive; ensure good sealing to prevent leakage.

5. Control System: Choose a group control system to achieve centralized monitoring, air velocity group regulation, fault alarm, and other functions.

6. Energy Consumption Indicators:** Pay attention to the unit energy consumption indicators of FFUs (such as power consumption per cubic meter of air volume) and select energy-efficient products.

Summary

Integrated fan filter units (FFUs) have become the standard configuration for modern electronic clean rooms, especially in the semiconductor and display panel industries with ultra-high cleanliness requirements. Through their modular, flexible, highly reliable, energy-saving, and excellent purification performance, they perfectly solve the extremely strict requirements of the electronics manufacturing industry for production environments. They are indispensable key technical equipment for ensuring high product yield, improving production efficiency, and realizing intelligent manufacturing. The level of their application directly reflects the advancement and reliability of clean room design.

Post time: Sep-15-2025