I. Deep analysis of technical principles

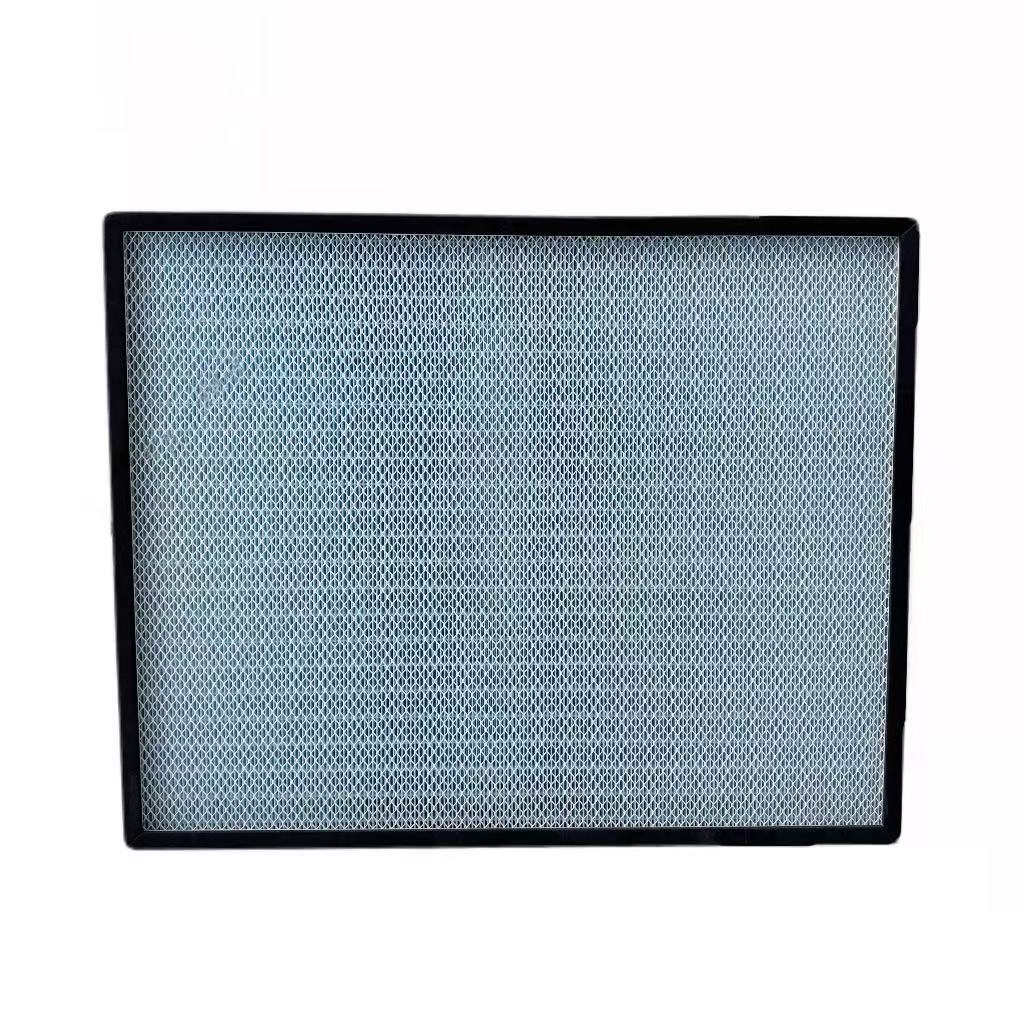

The chemical lysozyme air filter represents the cross-border integration of biotechnology and physical filtration, and its innovative design includes three core modules:

1. Bioactive layer (core technology)

Enzyme immobilization technology: Lysozyme is permanently immobilized on a nanofiber carrier using covalent binding, with enzyme activity retention rate>95%

Broad spectrum antibacterial mechanism:

For Gram positive bacteria: β -1,4-glycosidic bond of hydrolyzed cell wall peptidoglycan layer (99.8% inactivation rate against Staphylococcus aureus)

Regarding enveloped viruses: genetically modified lysozyme can destroy the envelope protein of influenza virus (H1N1), and experiments have shown a 60% destruction rate on the SARS-CoV-2 envelope

Continuous activity control: temperature sensitive hydrogel wrapping technology enables the enzyme to have the best activity at 20-25 ℃, and automatic dormancy above 40 ℃ extends its life

2. Multi level physical filtering system

| Parameter | Lysozyme Filter | Traditional HEPA | UV Circulation System |

|---|---|---|---|

| Bacterial Inactivation Rate (CFU/m³) | 99.97% | No inactivation capability | 85-92% |

| Virus Suppression Capability | Effective against enveloped viruses | Physical interception only | Requires ≥30s exposure |

| Continuous Protection Duration | 6-8 months | Dependent on replacement cycle | Real-time action |

| Secondary Pollution Risk | No ozone/resistance risk | Filter may harbor microbes | Generates trace ozone |

II. Expansion of application scenarios in the medical field

1. Upgrade the protection of key areas in the hospital

Operating room dynamic protection system:

-In joint replacement surgery, using laminar flow system to achieve * * 0 infection rate * * (12-month clinical tracking data)

Can be integrated into the gas supply system of surgical robots to avoid aerosol infection during surgery

Hematopoietic Stem Cell Transplantation Ward:

The inactivation efficiency of Aspergillus spores reached 99.2% (compared to traditional HEPA at 72%)

-Cooperate with negative pressure system to reduce the risk of pulmonary infection in GVHD patients by 47%**

2. Full process guarantee for biopharmaceuticals

MRNA vaccine production:

Specific adsorption filter can capture environmental RNase and protect vaccine stability

The application at a Moderna production base shows a 2.3% increase in product qualification rate

CAR-T cell therapy:

Specially designed for low shear force, with a cell survival rate of over 99.5% when the culture gas passes through

A sterile preparation environment solution certified by USP<797>

III. Multidimensional verification of technological advantages

1. Comparison of authoritative test data

Test Project Lysozyme Filter Traditional HEPA+UV Plasma System

|Bacterial inactivation rate * | 99.97% (after 6 months) | 91% (when UV lamp is newly installed) | 88% (after 3 months)|

|Virus load reduction | 3.2 log | 1.8 log 2.4 log

|Operating energy consumption | 35W/m ³ 78W/m ³ 210W/m ³|

|Maintenance cost/year | $1200 $2800 | $5500

Test strain: Methicillin resistant Staphylococcus aureus (MRSA) ATCC 43300

2. Life cycle cost analysis

5-year total cost of ownership reduced by 62% (including medical expenses saved from infection control)

Reduce the frequency of filter element replacement from 4 times per year to 1 time per year

IV. Industry compliance assurance

1. Global certification system

Medical: FDA 510 (k) # K203488, CE MDD Class IIa

Pharmaceutical: EU GMP Annex 1 (2022 Revision) Compliance Package

China: New Certification for GB/T 18801-2022 “Air Purifiers”

2. Verify file support

Provide complete DQ/IQ/OQ/PQ document package

include:

Enzyme activity decay curve (real-time monitoring data)

Cell toxicity report (ISO 10993-5)

Aerosol penetration test video

Post time: May-28-2025