The demand for high-temperature Mini Pleat HEPA filters in automotive spray drying oven production lines is not determined by a fixed number but by a series of engineering factors. To estimate the total demand for a production line, analysis is required on two levels: the demand for a single drying oven and the number of drying ovens in the entire production line.

I. Core Factors Determining the Filter Quantity for a Single Drying Oven

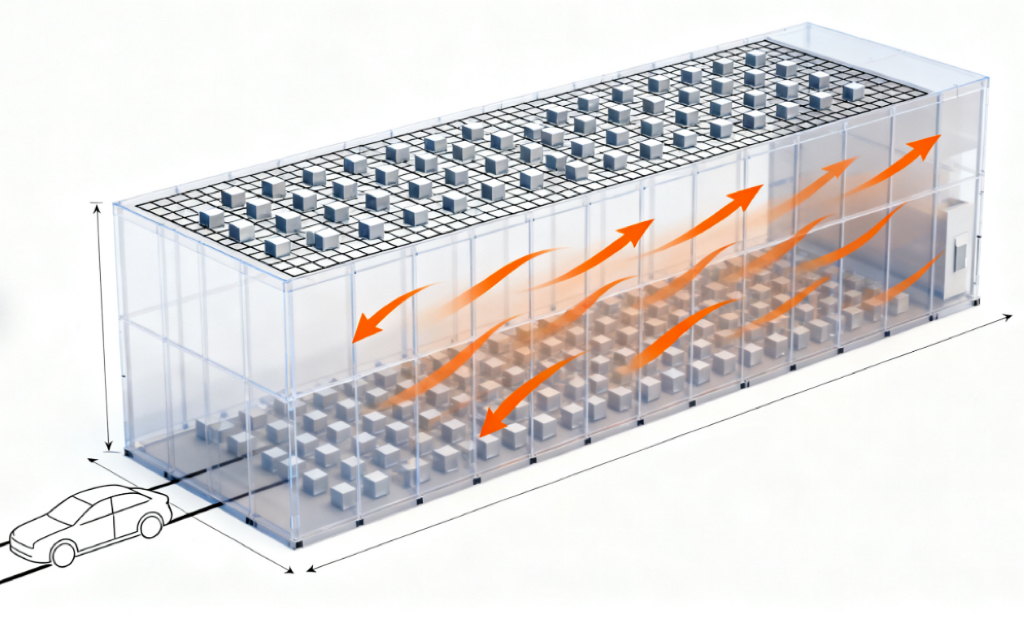

1. Oven Size (Volume) and Airflow Supply: This is the most critical factor. The larger the drying oven, the greater the total airflow required to ensure uniform temperature and velocity. The total airflow determines the total filtration area needed.

2. Air Supply System Design:

- Top Supply and Bottom Return: This is the most common design. The number of filters depends on the area of the supply ceiling. The supply ceiling is typically divided into multiple modular “high-efficiency filter units,” each containing one or a group of filters.

- Side Supply: In some smaller or specially designed ovens, side supply may be used, with a different filter arrangement.

3. Standard Size and Airflow of Individual Filters: High-temperature Mini Pleat HEPA filters come in common standard sizes, such as 610mm x 610mm x 150mm (24″ x 24″ x 6″) and 610mm x 1220mm x 150mm (24″ x 48″ x 6″).

- Each size of filter has its rated airflow (for example, a 610mm x 610mm filter may have a rated airflow between 1,500 – 2,000 m³/h, with specific values to be referenced from the manufacturer’s data). Dividing the total oven airflow by the rated airflow of a single filter gives a preliminary quantity.

4. Process Requirements for Cleanliness Level:

- The higher the paint quality requirement (e.g., for luxury brands), the higher the requirements for supply face velocity and cleanliness stability. Sometimes, the number of filters is increased, and the face velocity of individual filters is reduced to enhance dust-holding capacity and stability.

II. Filter Demand Composition for a Complete Automotive Coating Production Line

A complete coating line includes multiple drying processes, each with an independent drying oven:

1. Electrodeposition Drying Oven: For curing the electrodeposition primer.

2. Sealant Drying Oven: For drying the underbody sealant.

3. Intermediate Coating Drying Oven: For curing the intermediate paint layer. (Note: Some modern simplified processes may eliminate the intermediate coating.)

4. Color/Topcoat Drying Oven: This is the most important and demanding oven, for curing the outermost color and topcoat layers, with the strictest requirements for air cleanliness.

Therefore, a production line typically requires at least 2-4 sets of drying oven systems, each configured with a corresponding number of high-temperature high-efficiency filters.

III. Estimation Example (Focusing on the Most Important Topcoat Drying Oven)

Assuming the design parameters for a large topcoat drying oven are as follows:

- Vehicle passage time: 30 minutes

- Production rate: 60 vehicles/hour (i.e., one vehicle per minute)

- Oven length: Approximately 60 meters

- Air supply method: Full top supply

- Oven width: 8 meters

- Total airflow: Assumed to be 300,000 m³/h

- Selected filter: Standard size 610mm x 610mm, rated airflow 1,800 m³/h per filter

Quantity calculation:

- Total demand = Total airflow / Rated airflow per filter (300,000 m³/h ÷ 1,800 m³/h per filter ≈ 167 filters)

This is a theoretical calculation value. In actual design, engineers will divide the oven ceiling structure into several installation modules, and the number may be rounded to 168 or 170 to ensure even layout.

IV. Macro Estimation of Total Demand

Taking into account the above factors, we can make the following macro estimation for a complete automotive coating production line:

- Topcoat Drying Oven: The largest demand and highest requirements, typically ranging from 150 to 300 or more, depending on the production line scale.

- Intermediate Coating Drying Oven : Slightly less than the topcoat oven, but with a similar order of magnitude.

- Electrodeposition Drying Oven : Also a significant quantity.

- Sealant Drying Oven : Relatively smaller, with fewer filters required.

Conclusion:

For a modern, high-production-rate large automotive coating production line, the total demand for high-temperature Mini Pleat HEPA filters across all drying ovens is usually over 500 to 1,000. This figure represents a substantial consumption, which is why automotive manufacturers consider this as an important spare part for procurement and management.

The precise number must be determined during the production line design phase by equipment suppliers (such as Dürr, Eisenmann, etc.) based on specific process parameters and oven design drawings. The end user (the automotive plant) will then procure the exact models and quantities according to the equipment drawings and spare parts list.

Post time: Nov-01-2025