Operating high-efficiency filters at low airflow speeds is not only more durable but also more energy-efficient and environmentally friendly. This is a true situation when considering costs and environmental impacts from a “life cycle” perspective.

Here is a detailed explanation of why low-speed operation is more energy-efficient and environmentally friendly:

I. Direct Energy Savings: Significantly Reduced Fan Energy Consumption

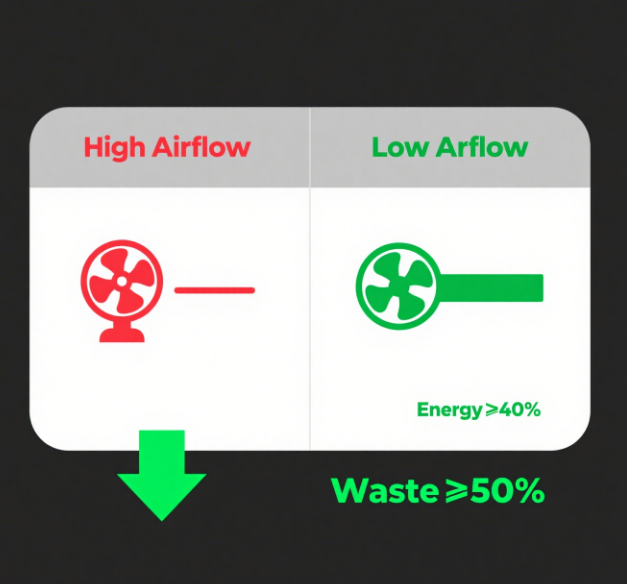

1. Fan Energy Consumption is Directly Related to System Resistance: The function of a fan is to overcome the resistance (static pressure) of air flowing through components such as ducts and filters. The power consumption (energy consumption) of a fan is directly related to the total system resistance (static pressure) it needs to overcome and the airflow volume.

2. Low Airflow Speed Equals Low Resistance: As previously mentioned, the initial resistance of the filter and the average resistance throughout its usage are both lower at low airflow speeds.

3. Effect: The total static pressure of the system decreases, and the power required by the fan to deliver the same airflow volume is significantly reduced. Fans are typically one of the largest energy-consuming units in HVAC systems, and even a small reduction in static pressure can save a considerable amount of electricity over the multi-year service life of a filter.

Example: A system with a designed airflow of 10,000 m³/h.

- High Resistance: The average operating resistance of the filter is 250 Pa.

- Low Resistance: By increasing the filter area to reduce airflow speed, the average operating resistance of the filter is 150 Pa.

- Savings: The system static pressure is reduced by 100 Pa. Assuming the fan efficiency is 60% and it operates for 8,000 hours per year, the annual electricity savings would be approximately: (100 Pa * 10,000 m³/h) / (3600 * 0.6) ≈ 0.463 kW. This translates to an annual savings of 3,700 kWh. Over the entire service life of the filter, the electricity cost savings are quite substantial.

II. Indirect Energy Savings: Extended Lifespan, Reduced Life Cycle Costs

1. Reduced Embodied Energy in Manufacturing and Transportation: Every filter, from raw material extraction, manufacturing, packaging to transportation to the customer site, consumes a significant amount of energy and water resources (referred to as “embodied energy”).

2. Extended Lifespan, Reduced Replacement Frequency: Operating at low airflow speeds can extend the filter lifespan from possibly one year to two years or even longer. This means that the number of filters that need to be manufactured, transported, and disposed of over the equipment’s life is halved.

3. Effect: This directly reduces the overall energy consumption and carbon emissions associated with filter production, embodying the “environmental protection” aspect of “energy-saving and environmental protection.”

III. Environmental Protection: Reduced Waste, Lower Environmental Burden

1. Reduced Solid Waste: Discarded filters are considered solid waste that needs to be landfilled or incinerated. Extending the replacement cycle directly means that the amount of solid waste generated is halved, reducing the pressure on waste treatment.

2. Reduced Pollution from the Production Process: Filter manufacturing plants themselves also produce emissions and waste. Reducing demand is equivalent to indirectly reducing this part of industrial pollution.

IV. Key Method to Achieve Low Airflow Speed Operation: Increasing Filter Area

1. To achieve low-speed operation, the most effective method is not to reduce airflow (since airflow is determined by cleanliness requirements) but to increase the size or quantity of high-efficiency filters to enlarge their effective filter area.

2. Common Designs: This is why, in large cleanrooms or high-end air purification systems, the following are commonly used:

- Pocket Filters (Multiple filter pockets provide a large area)

- V-shaped/Wedge Filters (Achieve large filter area in a compact space)

- Large Panel Filters

Although increasing the filter size means higher initial purchase costs, from a life cycle cost perspective, the electricity savings and reduced replacement frequency usually offset the increased initial investment within 1-2 years, after which it becomes pure net savings.

V. Comparison Table of High-Speed and Low-Speed Operation of High-Efficiency Filters

|

Aspect |

High-Speed Operation |

Low-Speed Operation |

Environmental and Energy-Saving Effects |

| Operating Resistance |

High |

Low |

Reduced fan energy consumption, direct electricity savings |

| Filter Lifespan |

Short |

Low |

Reduced replacement frequency, saved embodied energy |

| Waste Generation |

High |

Low |

Reduced solid waste, less environmental burden |

| Initial Cost |

Lower |

Higher |

Higher life cycle cost-effectiveness |

Operating high-efficiency filters at low airflow speeds is a crucial and effective energy-saving and environmentally friendly measure. It reduces energy consumption, waste generation, and resource savings. This is a typical “investing for efficiency” green design mindset, widely applied in modern green buildings and sustainable industrial design.

Post time: Aug-30-2025