Setting the terminal resistance of high efficiency air filters HEPA is crucial for balancing operating energy consumption and replacement costs helping users achieve energy savings and cost reduction

I Core Concepts

1 Initial Resistance The resistance of a new filter at its rated airflow

2 Terminal Resistance The resistance at which the filter needs replacing due to dust accumulation

3 Operating Range Filters operate between initial and terminal resistance with fans working against this resistance

II Core Principle

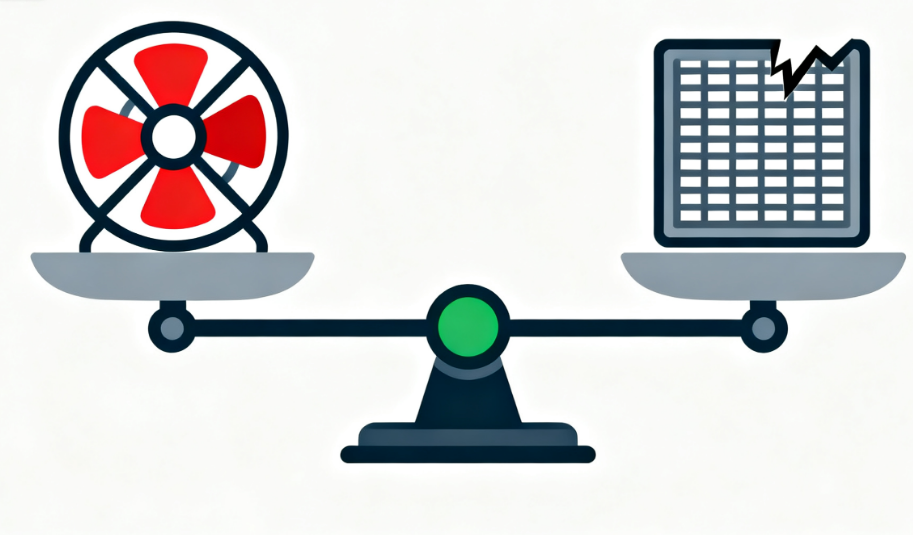

Setting terminal resistance is a balancing act between two costs

1 Energy Costs Higher resistance means more electricity use Higher terminal resistance leads to longer filter life but higher energy costs

2 Replacement Costs Include purchasing new filters and labor Higher terminal resistance extends filter life reducing annual replacements and costs

Total Cost Energy Costs Replacement Costs

The goal is to find the terminal resistance that minimizes total cost the sweet spot

III How to Set Terminal Resistance

Step One Establish Initial Benchmark

1 Manufacturers Recommendation Use the suggested terminal resistance from the filter manufacturer as a starting point

2 Industry Rule of Thumb If no recommendation exists set terminal resistance at twice the initial resistance

Step Two Monitor Analyze and Optimize

1 Install Monitoring Tools Use differential pressure gauges to track resistance changes

2 Collect Data Record resistance over the filters life and its actual service time

3 Analyze Costs Adjust terminal resistance eg 20 50 Pa and compare total costs to find the sweet spot

Step Three Make Decisions and Improve

After testing and comparing over several cycles identify the optimal terminal resistance for your system filter brand and local electricity prices

IV Advanced Strategies

1 Variable Frequency Drives Combine with variable frequency drives for precise energy management maximizing savings

2 Dust Concentration Adjust terminal resistance based on environmental dust levels to balance costs

3 Safety Limits Never exceed the manufacturers maximum resistance to avoid system issues

By following these steps and strategies you can optimize the terminal resistance of high efficiency air filters ensuring they operate efficiently and cost effectively

Post time: Sep-17-2025