Understanding the high efficiency and low resistance technology in high efficiency air filters is crucial for grasping their core technical value This concept represents the ultimate goal of filter performance and serves as a benchmark for assessing design and manufacturing quality

I Dissecting the Meaning of High Efficiency and Low Resistance

1 High Efficiency High efficiency filters are highly effective at capturing target sized particles typically with a minimum efficiency of 99 97 for 0 3 micron particles in HEPA filters ULPA filters have even higher requirements Ensuring purification effectiveness and meeting cleanliness standards is the filters fundamental mission

2 Low Resistance Low resistance means the filter offers minimal pressure drop measured in Pascals Pa for air passing through it This is a relative concept compared at the same efficiency level and rated airflow For example among two H13 filters the one with an initial resistance of 120 Pa is lower resistance than the one with 150 Pa Reducing fan energy consumption and lowering operating costs are key economic indicators

II The Deeper Meaning of High Efficiency and Low Resistance

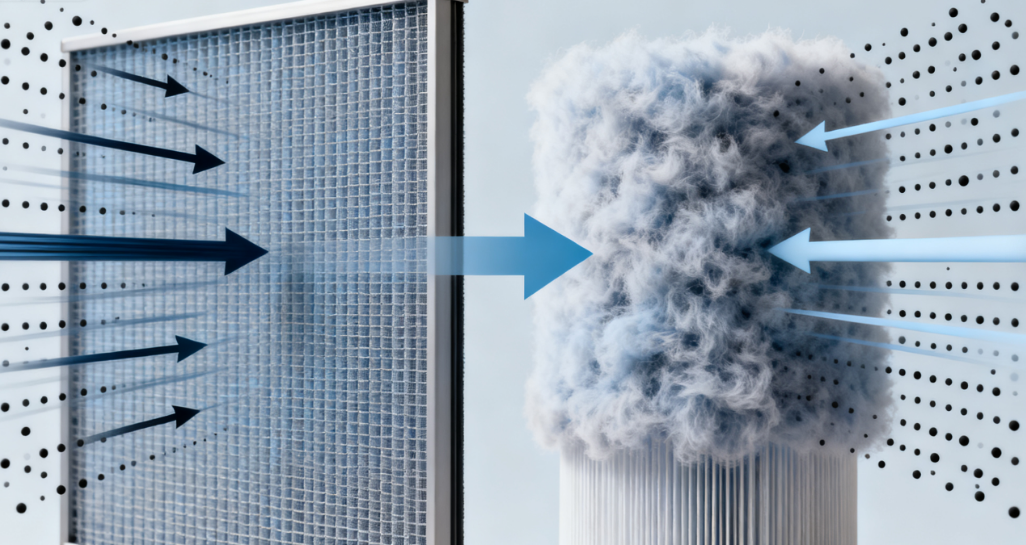

In traditional thinking high efficiency and low resistance were seen as a trade off To be highly efficient filters needed to be denser and thicker increasing air passing resistance To reduce resistance filters had to be looser decreasing efficiency The essence of high efficiency and low resistance technology is using advanced techniques to break this contradiction and achieve both characteristics

III Achieving High Efficiency and Low Resistance

This is the essence of filter material science and structural design mainly realized through the following three paths

1 Advanced Filter Material Technology Core Foundation

PP PTFE Electret Technology This is the key to achieving high efficiency and low resistance The principle is to charge polypropylene PP and other melt blown ultra fine fibers with a long lasting static charge electret through corona discharge

How to Achieve High Efficiency Charged fibers not only rely on traditional mechanical trapping mechanisms but also add a strong electrostatic adsorption effect greatly improving capture efficiency especially for 0 1 0 3 micron particles

How to Achieve Low Resistance The electrostatic effect allows the filter material to be fluffier with larger gaps between fibers ensuring very low air passing resistance

Technical Challenges The stability of the electret charge is crucial avoiding factors that can cause charge decay

Ultra Fine Fiber Technology Making fiber diameters extremely small usually less than 1 micron increases the number of fibers per unit volume providing more opportunities to capture particles This structure has much lower resistance than the dense structure formed by coarse fibers at the same efficiency

2 Intelligent Structural Design Performance Amplification Increasing Filter Area

Principle By increasing the depth and number of pleats the effective filter area is maximized within the same installation size

How to Achieve Low Resistance According to fluid mechanics increasing the filter area reduces the wind speed per unit area significantly lowering total resistance

Design Key Using partition boards or adhesive technology ensures uniform airflow channels between pleats preventing filter material adhesion

3 Gradient Structural Design Continuous Improvement

Principle The filter material shows a loose dense gradient change in the thickness direction

How It Works The fibers on the air entering side are relatively loose mainly intercepting large particles the fibers on the air exiting side are denser capturing fine particles

Advantages This structure ensures overall efficiency while preventing dust from clogging the surface and causing rapid resistance increase extending the service life and maintaining low resistance operation

IV The Ultimate Value of High Efficiency and Low Resistance Air Filters

1 Energy Saving and Cost Reduction Direct Cost Saving A reduction in initial resistance can save more electricity over the entire life cycle than the purchase price difference of the filter

2 Extended Life Indirect Cost Saving and Environmental Protection Low resistance means the filter has more dust holding space extending its service life and reducing annual replacement frequency saving procurement and labor costs This also reduces solid waste

3 Improved System Reliability Low resistance operation provides a larger pressure difference margin for the system making airflow regulation more flexible and system operation more stable

High efficiency and low resistance is not just a marketing slogan but a concentrated reflection of filter technology progress It ensures high filtration efficiency while significantly reducing air passing resistance bringing users the core value of energy saving long life and low total cost When choosing a filter high efficiency and low resistance products are the best choices that combine performance and economic benefits

Post time: Sep-18-2025