Selecting a Gel Seal HEPA filter is a highly precise task, far more complex than choosing a standard HEPA filter. In addition to focusing on the performance of the filter itself, it is essential to consider the entire supporting system. When selecting a Gel Seal HEPA filter, pay attention to the following key technical details, which can guide your decision-making process:

Core Components: Must Be Fully Compatible

A Gel Seal system is not just a standalone filter but a precision system composed of four major components. Any mismatch among these components can lead to system failure.

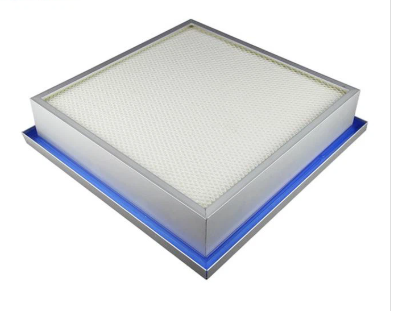

1. Gel Seal HEPA Filter Body

1.1 Dimensional Accuracy (Extremely Important): The insertion depth of the filter’s “knife edge” is pre-designed. The absolute dimensions (length, width, thickness) of the outer frame (including the knife edge) and the tolerance for straightness and flatness of the knife edge itself are extremely stringent (typically within ±0.5mm). Poorly made filters with inaccurate dimensions can lead to inconsistent insertion depths, causing some areas to not seat properly while others are too tight, resulting in leaks or installation difficulties.

1.2 Structural Strength: The filter frame must have sufficient strength and rigidity (usually made from thick aluminum profiles) to ensure no deformation during handling, insertion, and normal use. Any minor deformation can compromise the seal.

2. Dedicated Gel Trough Installation Frame

2.1 Compatibility: The width and depth of the frame’s gel trough must perfectly match the thickness and insertion depth of the filter’s knife edge. This is the most critical matching relationship and must be clearly confirmed with the supplier.

2.2 Material and Treatment: The frame is typically made of aluminum alloy or stainless steel. Check if the surface has been treated with anodizing or powder coating to ensure corrosion resistance and ease of cleaning.

2.3 Levelness and Flatness: The upper surface of the installation frame must be absolutely level, and multiple frames within the same installation surface must maintain a very high degree of flatness. Otherwise, filters installed at different heights can cause airflow disturbances and cleaning dead zones.

3. Gel Trough Sealant Performance Selection:

3.1 Non-Drying Type: Suitable for environments with relatively low relative humidity (<60%), offering a longer service life.

3.2 Drying Type: Suitable for high-humidity environments, where it remains pliable and does not dry out easily, though it may require more frequent maintenance.

3.3 Compatibility: Ensure the sealant is compatible with the filter frame material (usually aluminum alloy) and the installation frame material to prevent chemical reactions that could cause corrosion.

3.4 Filling Quantity: The amount of sealant injected into the frame’s gel trough is strictly regulated. Too much can overflow and contaminate the filter or the site, while too little will fail to create an effective seal.

4. FFU (Fan Filter Unit) or Supply Air Plenum

4.1 Interface Compatibility: If the filter is to be installed on an FFU, ensure that the FFU’s outlet dimensions and installation method perfectly match the gel trough frame.

4.2 Performance Compatibility: The FFU’s fan must be capable of overcoming the slightly higher resistance inherent in the Gel Seal system compared to conventional sealing methods and provide stable, uniform airflow.

Key Performance Parameters

5. Filter Efficiency: Choose the appropriate efficiency level based on the required cleanliness grade, such as H13 (efficiency ≥99.95% for MPPS) or H14 (efficiency ≥99.995% for MPPS). Demand that the supplier provide authoritative third-party test reports in accordance with EN 1822 or GB/T 6165 standards.

6. Rated Airflow and Face Velocity: Confirm that the filter’s rated airflow meets your design requirements. Gel Seal filters also follow the principle that lower face velocity extends service life. When airflow is fixed, select a larger-sized model (with a larger filter area) to reduce face velocity, thereby lowering resistance, extending service life, and saving energy.

7. Initial Resistance: At the rated airflow, the lower the resistance, the better, as it directly affects operating energy consumption. When comparing different products, choose the one with lower initial resistance under the same efficiency level.

Safety and Auxiliary Configurations

8. Mechanical Clamping Device: Although the gel seal provides the primary seal, it is strongly recommended to choose a system and frame with a mechanical clamping device (such as clamps or bolts). This provides a double safeguard: preventing the filter from being “sucked out” in extreme conditions (such as a sudden increase in negative pressure). It also facilitates the replacement and adjustment of individual filters without compromising the overall seal.

9. Leak Detection and Test Ports: High-quality installation frames will have reserved DOP/PAO aerosol injection ports and sampling ports, facilitating on-site scan leak testing (PAO test), which is a necessary means to confirm successful installation and subsequent maintenance.

Supplier and Service

10. Professional Installation and Commissioning: The success of a Gel Seal system relies 30% on the product and 70% on the installation. It is essential to require the supplier to provide a professional and experienced installation team, including:

10.1 Leveling and straightening the installation frame.

10.2 Standardized injection of the sealant.

10.3 Precise and smooth insertion of the filter.

10.4 On-site leak testing after installation.

10.5 Avoid allowing inexperienced construction teams to install it on their own.

11. After-sales Service and Agreement: Clarify the expected service life and replacement cycle of the sealant; understand the service process and costs for filter replacement; ensure the supplier can provide long-term technical support and service.

When selecting a Gel Seal HEPA filter, be sure to confirm the following details:

1. Dimensional Matching: Do the dimensions of the filter’s knife edge perfectly match the gel trough of the installation frame?

2. Frame Levelness: Will the supplier ensure the absolute levelness and flatness of the installation frame?

3. Sealant Selection: Is the type of sealant (non-drying/drying) suitable for my environmental humidity?

4. Mechanical Clamping: Does the system come with a mechanical clamping device as a double safeguard?

5. Leak Detection Ports: Are PAO test ports reserved on the installation frame?

6. Performance Report: Can a third-party EN1822 filter efficiency test report be provided?

7. Professional Installation: Will the supplier commit to professional team installation and commissioning?

8. After-sales Maintenance: Are the replacement cycles and services for the sealant and filters clearly defined?

Selecting a Gel Seal HEPA filter essentially involves choosing a reliable system solution and a professional service supplier, rather than just purchasing a product. Avoid sacrificing the integrity, compatibility, and professionalism of the system for the sake of a lower price; otherwise, the losses from a leak will far exceed the cost savings initially achieved.

Post time: Sep-04-2025