The technical guidance for HEPA/ULPA filters in powder injection cleanrooms is a highly specialized and systematic task. Powder injections are high-risk sterile products, and maintaining a clean environment is crucial for product quality. Below is a concise framework for comprehensive technical guidance covering the entire lifecycle from selection to disposal.

I Core Objectives and Principles

1 Objective Ensure the cleanroom air environment continuously meets GMP and GB 50073 standards with core areas like filling zones typically achieving ISO 5 Grade A standards

2 Principles

Risk Management Prioritize reducing contamination and cross-contamination risks

Compliance All selections installations tests and management must comply with GMP and regulatory requirements

Lifecycle Cost Aim for the lowest Total Cost of Ownership TCO not just low purchase prices

Data-Driven Decisions Base decisions on monitoring data and validation results not on experience alone

II Detailed Technical Guidance

Phase 1 Design and Selection

1 Demand Analysis and Assessment

Evaluate layout airflow patterns and temperature humidity requirements

Determine filter efficiency grades for different cleanroom classes eg H14 for Grade A B H13 for Grade C D

Calculate rated airflows for HVAC units and FFUs

2 Filter Selection Recommendations

Efficiency and resistance Recommend high-efficiency low-resistance filters with MPPS efficiency certification eg H13 H14 per EN 1822

Filter media Suggest ultra-fine glass fiber or high-quality electrostatic filter media assessing chemical resistance and charge stability

3 Product Structure

Sealed construction Emphasize the importance of frame sealing techniques to ensure leak-free performance

Frame material Recommend rust-resistant corrosion-resistant materials like anodized aluminum stainless steel or galvanized frames

Phase 2 Installation Commissioning and Validation

1 Installation Supervision

Timing Install after all interior work and initial cleaning are complete

Personnel and tools Trained operators in cleanroom attire using specialized tools

Installation Ensure proper sealing and symmetrical tightening to prevent leaks

2 On-Site Testing and Validation IQ OQ

Integrity testing leakage test A mandatory and critical test using PAO or DOP aerosol and a photometer for scanning

Standards Leakage rate must not exceed 0.01 at any point

Additional tests Airspeed volume pressure differential and cleanliness level verification

Phase 3 Operation Maintenance and Replacement

1 Daily Monitoring

Differential pressure monitoring Install and monitor pressure gauges daily

Environmental monitoring Continuous particle and microbial monitoring

2 Replacement Strategy

Terminal resistance method Replace when resistance doubles or airflow cannot be adjusted to required levels

Periodic replacement Consider replacement after prolonged use eg over 1 year based on environmental monitoring

Emergency replacement Immediate replacement for failed integrity tests or physical damage

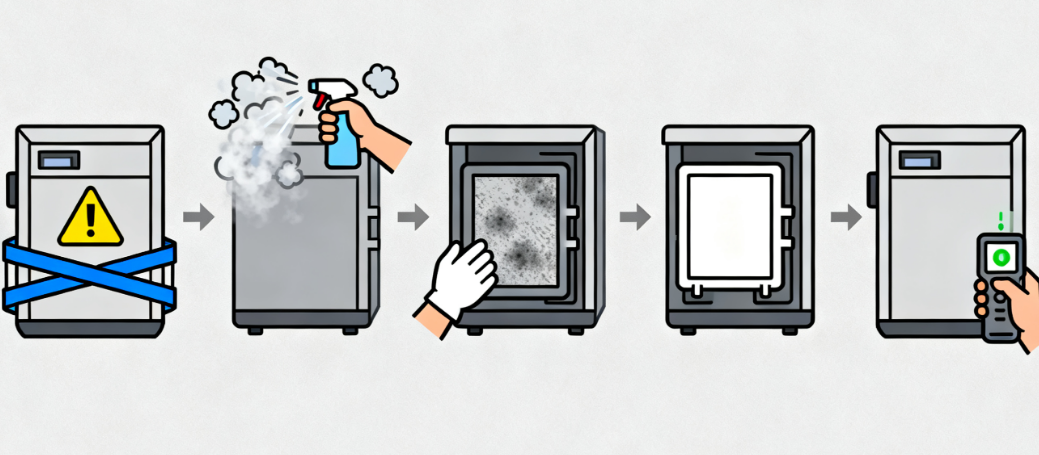

3 Replacement SOP Develop a detailed standard operating procedure for safe isolation disinfection removal installation and validation

Phase 4 Management and Training Support

1 Documentation Assist in establishing a filter management file system with detailed records for each unit

2 Personnel Training Train relevant staff on filter principles importance replacement procedures and emergency response

III Value Proposition

Compliance Risk Reduction Ensure continuous GMP compliance and successful audits

Product Quality Assurance Prevent powder contamination from air pollution safeguarding patient safety

Cost Optimization Extend filter life and reduce energy and spare parts costs through scientific selection and precise replacement strategies

Professional System Establishment Help build a scientific standardized and traceable management process enhancing team expertise

In summary the technical guidance for HEPA/ULPA filters in powder injection cleanrooms is a professional safeguard ensuring the critical air purification system remains robust and reliable

Post time: Sep-20-2025