Technical Parameters to Consider When Selecting FFU

Selecting an FFU (Fan Filter Unit) is a highly technical task, and the correctness of the selection directly affects the performance, energy consumption, and long-term operating costs of a cleanroom. The following are the core technical parameters that need to be considered during the selection process, which can be divided into three main categories: performance parameters, structural parameters, and control & compliance.

I. Core Performance Parameters (Determining Purification Effect and Energy Consumption)

These are the foundation of the selection process and must strictly match the design requirements of the cleanroom.

1. Filter Efficiency: The core performance of the filter, which refers to its ability to capture particles of a specific size. This is selected based on the cleanroom classification requirements.

- HEPA: Efficiency ≥99.99% for 0.3μm particles (H13) or ≥99.995% (H14), suitable for ISO Class 5-6.

- ULPA: Efficiency ≥99.9995% for 0.12μm particles (U15) or higher, suitable for ISO Class 3-5.

2. Rated Airflow: The volume of air (m³/h) that the FFU can deliver per unit of time under rated frequency and zero static pressure conditions. It is calculated based on the designed face velocity (typically 0.35-0.55 m/s) and the effective air delivery area of the FFU. Ensure that the airflow meets the required air change rate.

3. External Static Pressure: The ability of the FFU to maintain the rated airflow after overcoming the resistance of its own filter, return air grille, and other system resistances (unit: Pa). This is a critical but often overlooked parameter. A margin should be left (typically ≥100-120 Pa) to cope with the increased resistance due to filter dust accumulation, preventing airflow decay.

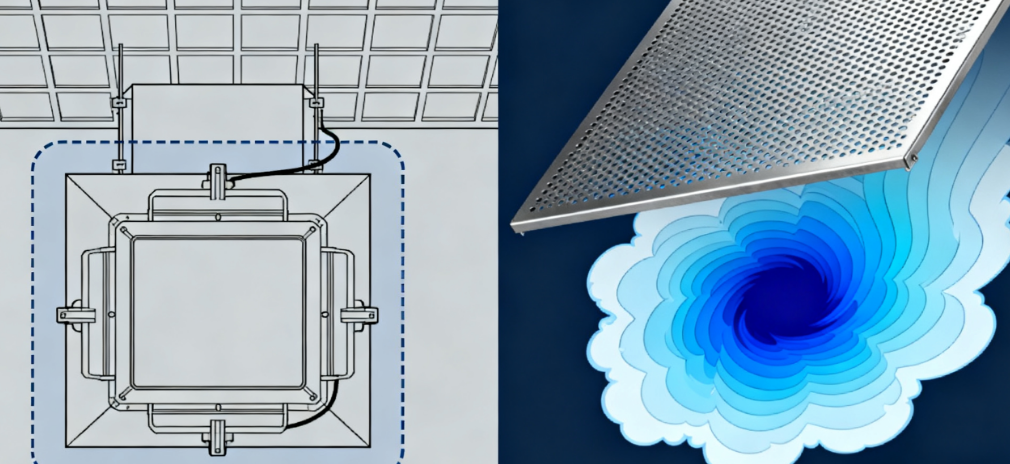

4. Air Velocity Uniformity: The stability of the air velocity at various points on the FFU’s air outlet surface, typically required to be ≤±10% to ±15%. Poor uniformity can lead to disordered airflow, vortices, and ineffective pollutant removal.

5. Noise Level: The sound pressure level (unit: dB(A)) measured at a distance of 1.5 meters directly below the FFU under rated airflow conditions. For areas where personnel work for extended periods, low-noise models should be selected (e.g., ≤52-55 dB(A)). EC motors are generally quieter.

6. Motor and Energy Consumption: The type of motor and its input power (unit: W). EC (brushless DC) motors must be chosen. Their efficiency (>80%) is significantly higher than that of AC motors, resulting in substantial energy savings, smooth speed regulation, long life, and low heat generation.

II. Structural and Material Parameters (Determining Reliability, Durability, and Applicability)

These parameters determine the reliability, durability, and suitability of the FFU for different environments.

7. Casing Material: Galvanized steel is the most commonly used material, offering good corrosion resistance and cost-effectiveness, suitable for most electronic and optical cleanrooms. Stainless steel (SUS304/SUS316) is corrosion-resistant and easy to clean, making it suitable for biopharmaceutical, food, and medical environments with hygiene or chemical corrosion requirements.

8. Dimensions and Specifications: The external dimensions (length * width * height) of the FFU must match the ceiling grid module of the cleanroom. The most common specifications are 1200mm x 600mm (metric) and 1175mm x 575mm (imperial 4′x2′). Custom sizes are available.

9. Filter Replacement Method: How to replace the consumables (filters). The “bottom replacement” method is strongly recommended. Personnel do not need to enter the technical plenum; they can safely and quickly replace the filters from within the cleanroom using quick-release mechanisms (such as spring clips or eccentric wheel handles) and ensure zero leakage with gel sealing.

10. Airflow Equalizing Device: The metal perforated plate or mesh located below the filter. This internal structure ensures uniform airflow velocity and is crucial for meeting the required air velocity uniformity.

III. Control and Compliance Parameters (Determining Intelligence Level and Quality Assurance)

These parameters determine the level of intelligence and quality assurance of the FFU.

11. Control Method:

- Individual Control: Each unit has its own speed controller, suitable for very small-scale applications.

- Group Control: One master controller manages dozens of FFUs, offering good cost-effectiveness.

- Networked Intelligent Control (Preferred): Connected to a central control system via an RS-485 interface, enabling remote monitoring, speed adjustment, fault alarms (such as differential pressure alarms), and energy management. This is the standard for large-scale projects.

12. Certifications and Test Reports:

- Filter Test Reports: Require the supplier to provide third-party authoritative test reports on filter efficiency and integrity (such as EN1822, IEST-RP, ISO 29463).

- Whole Machine Certification: Check if the entire unit has passed safety certifications such as CE or UL.

- Factory Leak Test Report: Require a PAO/DOP scan leak test report for each FFU to ensure no leakage.

IV. Quick Guide for FFU Selection Process

1. Clarify Requirements: Determine the cleanliness level (filter efficiency), temperature and humidity, room size, and layout (airflow, dimensions).

2. Calculate Airflow: Calculate the rated airflow for each unit based on the face velocity (e.g., 0.45 m/s) and the effective area of the FFU.

3. Determine Static Pressure: Choose a model with an external static pressure ≥120 Pa to leave sufficient margin.

4. Select Motor: Unconditionally select EC motor models.

5. Determine Structure: Choose the material (galvanized steel/stainless steel) based on the environment.

6. Plan Control: Select the control method (individual/group/networked) based on the project scale.

7. Verify Qualifications: Request certifications and test reports to ensure product quality.

8. Comprehensive Evaluation: Do not focus solely on the unit price. A comprehensive evaluation of performance, energy consumption, control methods, and after-sales service should be conducted to calculate the total cost of ownership (TCO) over the long-term operation.

By systematically considering the above parameters, you will be able to select the most suitable FFU product for your project, laying a solid foundation for the stable and efficient operation of the cleanroom.

Post time: Oct-18-2025