FAF Products

Fiberglass Pocket Filter

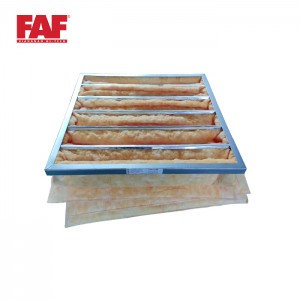

I. Product Introduction

Fiberglass Pocket Filters are high-efficiency air filters designed for HVAC systems, cleanrooms, and industrial applications. They consist of durable fiberglass media pleated into "pocket" or bag-style configurations, offering a large surface area for capturing dust, particles, and contaminants. These filters are ideal for applications requiring high airflow with low resistance.

II.Product advantages

The FAF GXM pocket filter comes with pockets made from microfine fiberglass in a Special design. The result is optimized air distribution for high indoor air quality in combination with moderate energy consumption. Whether installed as a final filter in office buildings, schools, or shopping malls, or as a prefilter for industrial processes, the FAF GXM filter is an excellent option for both a better indoor climate and low operating costs.

Improved Process Performance

The specially designed tapered pockets of the FAF GXM filter guide air with a continuous velocity through the filter. Complemented by a more uniform use of the filter surface, the FAF GXM filter provides high-quality air. This filter performs 20% above the minimum efficiency requirement (ME) of the EN779:2012 standard, so that indoor conditions for building users and industrial processes are greatly improved.

Environmental Savings

The FAF GXM filter owes its moderate energy use to its innovative geometric filter design, which results in the pressure drop increasing very gradually during the lifetime of the filter. Low energy consumption and related reduced carbon dioxide emissions directly contribute to a better environment.

Beneficial Total Cost of Ownership

With the purchase of air filters, operating costs during the entire life cycle will typically have a higher financial impact than solely the initial investment. The gradual pressure drop increase of the FAF GXM filter directly translates into reduced energy costs. Because of the innovative design with tapered pockets, this air filter’s lifetime is longer, meaning fewer filter replacements per year and additional cost savings.

III.Product parameters

Parameter of the Fiberglass Pocket Filter

| EN779 | M6 – F9 |

| ASHRAE 52.2 | MERV 11 – 15 |

| ISO 16890 | ePM 2.5 50%, ePM1 65%, 85% |

| Filter Depth (mm) | 525, 635 |

| Media Type | Fiberglass |

| Frame Material | Galvanized Steel |

| Special Size Available | Yes |

| Antimicrobial Available | Optional |

| Single Header | Yes |

| Recommended Final Resistance | 450 Pa |

| Max. Operating Temperature | 66˚C |

IV. Product Applications

HVAC Systems: Commercial buildings, hospitals, data centers.

Industrial Processes: Paint booths, chemical manufacturing, food processing.

Cleanrooms: Pharmaceutical labs, electronics manufacturing.

Exhaust Systems: Fume and odor control.

V. FAQ

Q1: How often should pocket filters be replaced?

A: Typically every 3–6 months, depending on dust load and airflow conditions.

Q2: Can they handle high humidity?

A: Yes, fiberglass media resists moisture, but prolonged wet conditions may require synthetic alternatives.

Q3: Are they recyclable?

A: Fiberglass media is not easily recyclable; dispose per local regulations.