FAF Products

V-bank filter for turbomachinery and gas turbine air intake systems

I.Product introduction

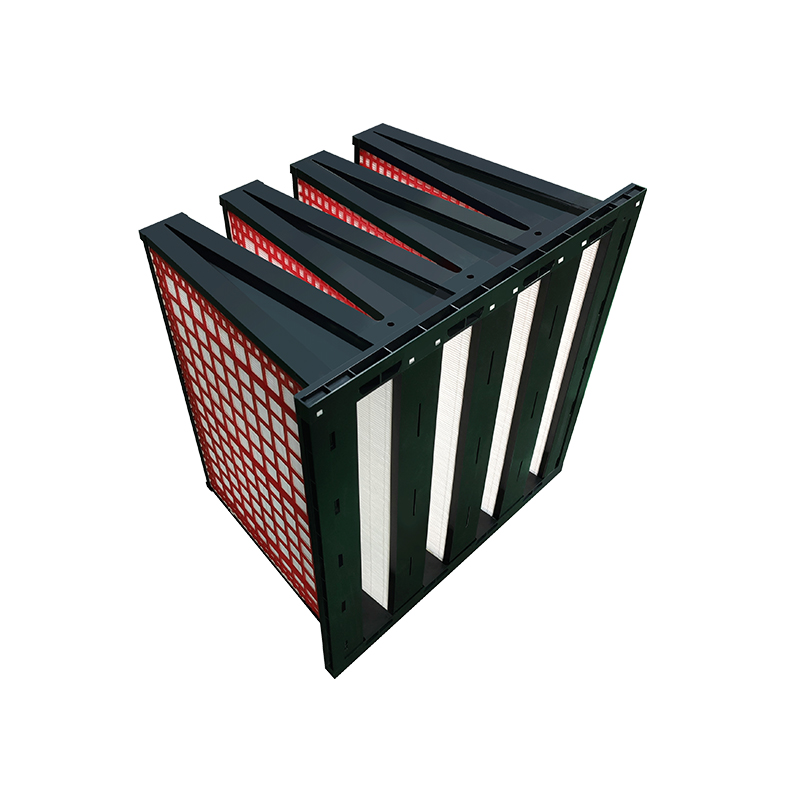

FAFGT is a compact, vertically pleated high-efficiency EPA filter used in turbomachinery and gas turbine air intake systems where low operational pressure drop and reliability are important.

The construction of FAFGT feature vertical pleats with hot-melt separators for drainage. The hydrophobic filter media packs are bonded to the inner surface of a robust plastic frame that features double sealing to eliminate bypass. A reinforced frame with a solid header ensures 100% leak-free performance. The vertical pleats and open separators allow trapped water to drain freely from the filter during operation, thus avoiding re-entrainment of dissolved impurities and maintaining low pressure drop under wet and high humidity conditions.

Each filter grade is individually optimized for lowest pressure drop and maximum life. A polyurethane gasket is permanently fixed to the filter frame, limiting the risk of filter leakage during installation.

The FAFGT filters eliminate bypass air, extend turbine life, prevent fouling and corrosion, reduce maintenance costs and reduce gas turbine CO2 emissions per MWh when using EPA filters. They are suitable for all installations where safety and reliability are important, including corrosive and wet/high humidity conditions.

Filter class: F7 - H13

FAFGT filters are tested for efficiency in accordance with the latest standard for air filters including EN 779:2012, ASHRAE 52.2:2017, ISO 16890:2016 and EN1822:2019.

II.Product advantages

• Low operational pressure drop, even when wet, with patented built-in drainage.

• Sealed on all sides and featuring our patented double sealing process.

• Resistant to turbulence and extreme pressure drop.

• Patented Aerodynamic support grid for lower pressure drop.

• Optimized media area for the lowest pressure drop at EPA efficiency.

III.Product parameters

|

Application |

All installations where safety/reliability is important. All installations with high humidity/heavy rain |

|

Filter Frame |

Plastic molded, ABS |

|

Media |

Glass fiber |

|

Relative Humidity |

100% |

|

Recommended final pressure drop |

600 Pa |

|

Separator |

Hot-melt |

|

Gasket |

Polyurethane, endless foamed |

|

Grille, Downstream |

Support grid for filter media |

|

Sealant |

Polyurethane |

|

Installation options |

In a separate bank, from the upstream or downstream sides. Can be close-coupled in a reverse-flow configuration |

|

Max Airflow |

1.3 x nominal flow |

|

Fire rating: Available according to DIN4102 class b2 rating on request |

|

|

Reverse flow version: With support metal grid available on request |

|

|

Max temperature (°C) |

70°C |

|

Filter Class ASHRAE |

MERV 13 |

IV.Product applications

1. Gas Turbine Inlet Air Filtration

Protects compressor blades from dust, sand, salt, and airborne particulates.

Prevents fouling & erosion, maintaining turbine efficiency and lifespan.

Critical for power plants, offshore platforms, and aeroderivative turbines.

2. Industrial Turbomachinery

Compressor stations (oil & gas pipelines) – Filters abrasive particles in desert/coastal environments.

Aero engines (ground testing) – Simulates clean airflow during performance validation.

3. Harsh Environment Solutions

Desert climates – Multi-stage filtration (V-bank + coalescer) for sandstorms.

Marine/offshore – Corrosion-resistant SS316 frames with hydrophobic media.

Arctic conditions – Heated housings prevent ice buildup on filter media.

4. Energy Efficiency Optimization

Low ΔP design (<150 Pa @2m/s) reduces parasitic power loss.

Extended service intervals – High dust-holding capacity vs. panel filters.

V.FAQ

Q: What Payment term you are running?

A:50% deposit paid in advance,50% of the balance is paid before delivery.

Q3. How about your delivery time?

A: Generally, it will take 7 to 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q: Do you provide samples? Is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.