Johnson & Johnson was founded in 1886, with a total revenue of $94.943 billion in 2022. It is the largest and diversified medical and health care products and consumer care products company in the world.

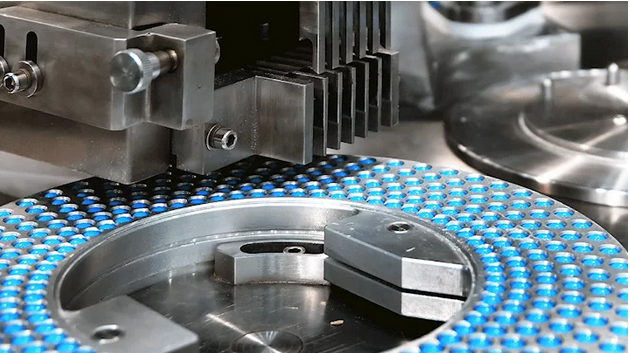

The sterile filling line of Johnson & Johnson has the most stringent cleaning requirements. The whole heat removal tunnel oven needs to meet the requirements of ISO Grade 5 clean room, and the glass bottles, ampoules and syringes should be disinfected before aseptic filling.

So far, in order to reach the ISO 5 level of cleanliness, the filter needs to be baked or tempered before safe use in production. These processes lead to smoke discharge, resulting in shutdown during smoke discharge and hot zone cleaning.

In addition, the sterilization process means burning the botulinum toxin at high temperature (>280 ° C). Unfortunately, when the tunnel temperature increases or decreases, or when the temperature changes under steady-state conditions at high temperature, some high-temperature filters will "emit" particles. The emission of these particulates will have a negative impact on the production and quality, leading to expensive shutdown and filter replacement.

Solution:

It is well known that maintaining the normal operation of the sterile filling production line is crucial to sustainable business growth. Therefore, it is essential to run the pyrogen tunnel as long as possible without interruption.

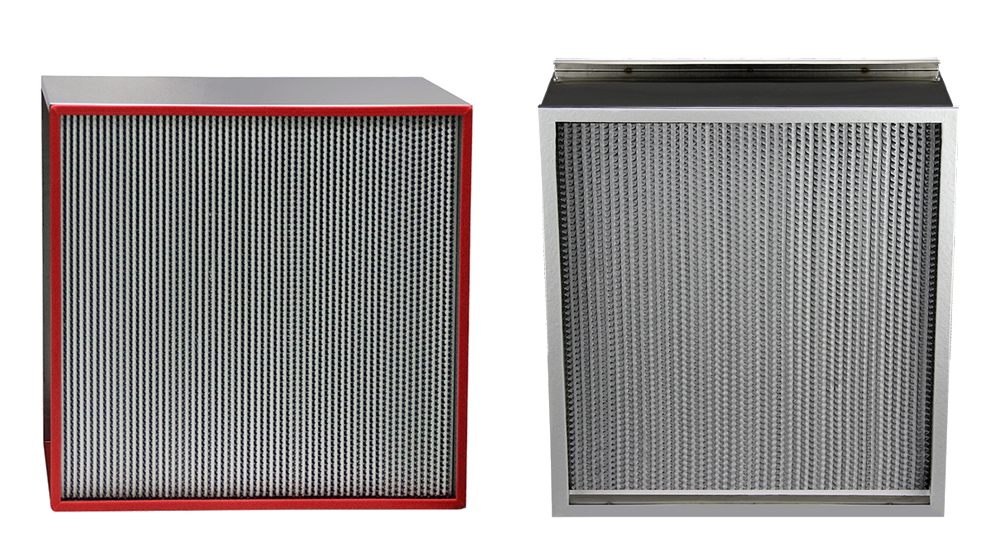

FAF HT 250C and FAF HT 350 series can provide protection for all processes from normal temperature process to high temperature cleaning process. It is suitable for installation where the working temperature is up to 250 ° C-400 ℃.

The frame is made of stainless steel or aluminum alloy, which is easy to disassemble. The folds are evenly separated and supported by conical aluminum foil corrugated plates to prevent damage to the medium.

The conical aluminum foil corrugated plate can also ensure the uniform air flow of the entire media packaging and maintain the packaging stability. The filter has passed EN779:2012 and ASHRAE 52.2:2007 filter grade certification.

Through the above measures, it can effectively realize the wide application of Johnson & Johnson Pharmaceutical in the United States and promote the development of the pharmaceutical industry.

Post time: Mar-13-2023